Three Papers at SIGGRAPH 2025

We are happy to announce that three papers from our research group have been accepted for presentation at SIGGRAPH 2025, with one receiving special recognition.

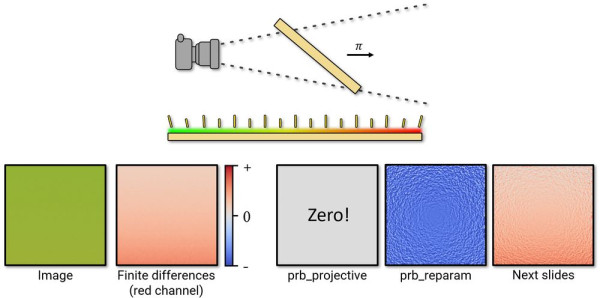

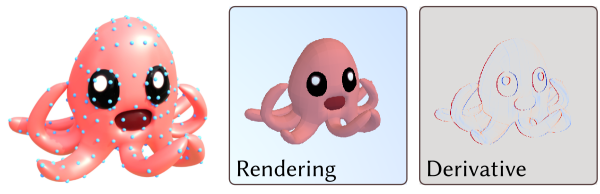

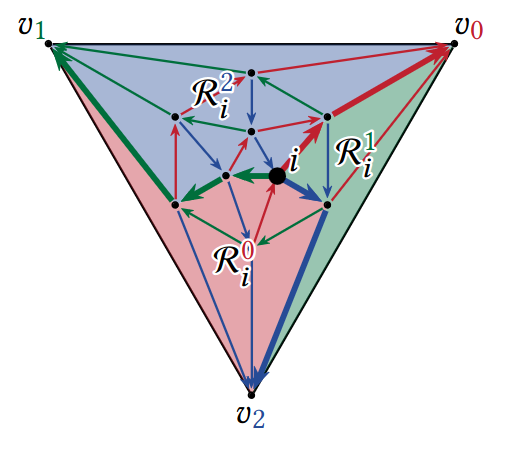

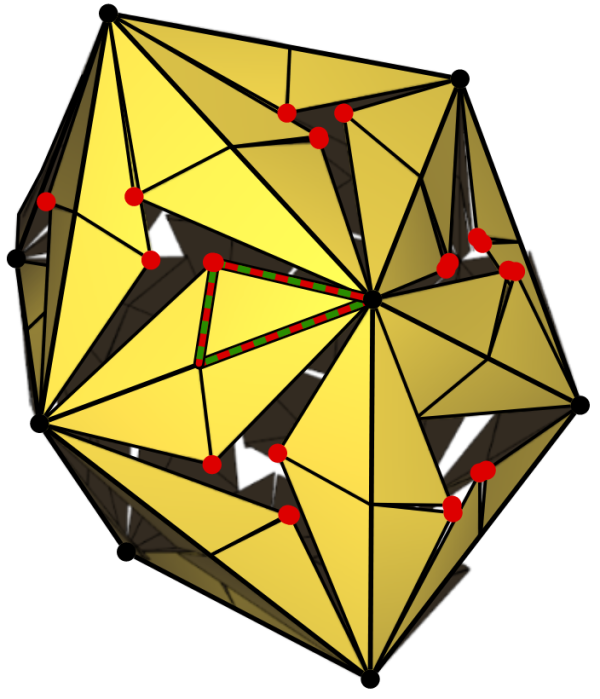

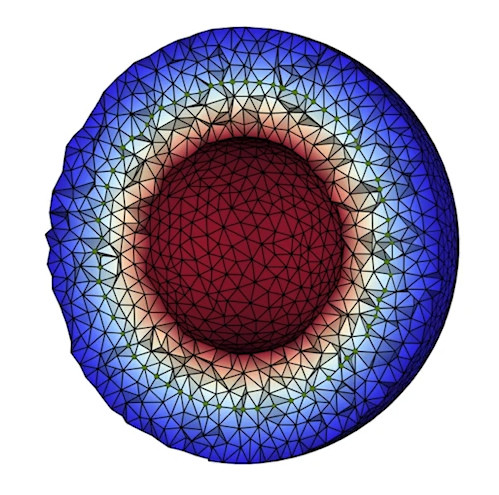

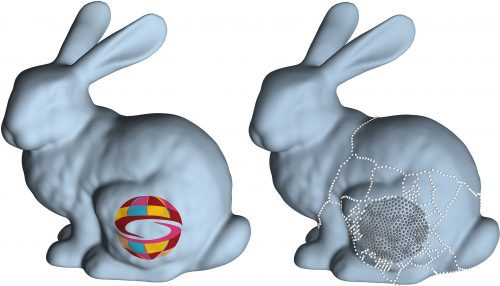

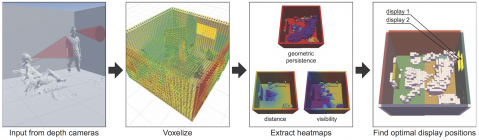

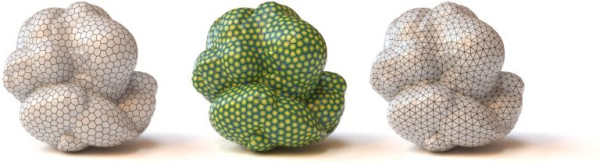

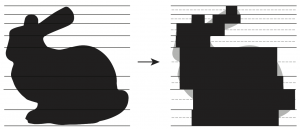

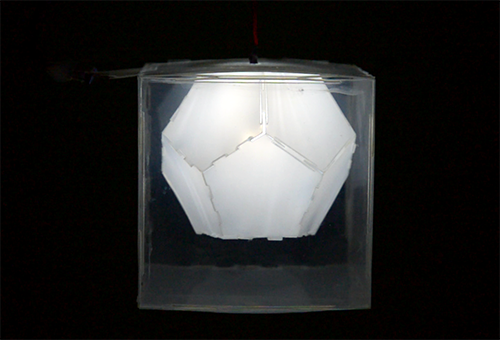

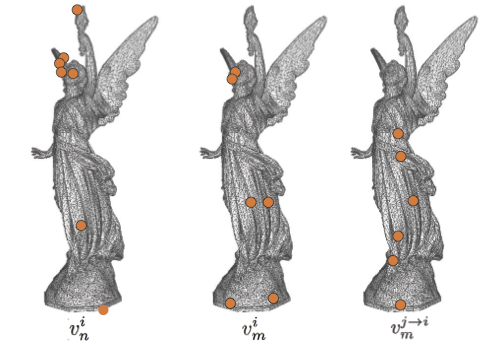

Our accepted contributions span diverse areas of computer graphics. "A Polyhedral Construction of Empty Spheres in Discrete Distance Fields" introduces a new algorithm for calculating maximum empty spheres. "Differentiable Geometric Acoustic Path Tracing Using Time-Resolved Path Replay Backpropagation" extends differentiable path tracing techniques to acoustic simulations and enables gradient-based optimization in sound propagation modeling. "Moment Bounds are Differentiable: Efficiently Approximating Measures in Inverse Rendering," which earned the Best Paper Award — Honorable Mention at the conference, demonstrates the differentiability of moment bounds with applications to inverse rendering.